The Anaerobic Digestion Process

A quick guide to anaerobic digestion

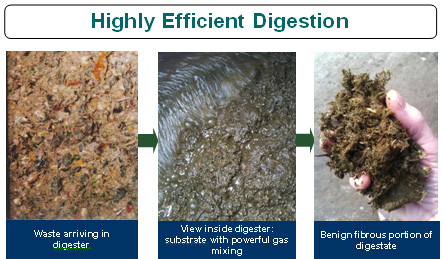

- Mix animal slurry with other organic matter (e.g. food waste or crops)

- Put the mix into a sealed tank with agitation and heat to around 38°C

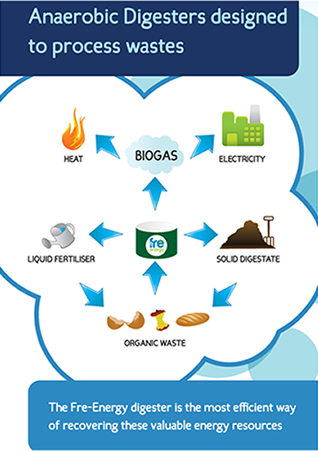

- The bacteria present break down the organic parts releasing bio-gas (about 60% methane and 40% carbon dioxide)

- The gas is used to generate heat and renewable electricity by fuelling a generator

- The resulting “soup” (digestate) is used as a bio-fertiliser with its nutrients in a readily available state

You will find answers to many of the questions you may have on the FAQs page. If you have further questions please do not hesitate to contact us.

Further information:

Our patented de-gritting and foam alleviation technology

Our own Anaerobic Digestor installation at Lodge Farm

Proven Technology

Supported by three years' real-time data, Fre-energy's unique technology demonstrates that it is not necessary to have to choose or prioritise sustainable food production vs. constant reliable energy production vs. efficient organic waste management, as this proven technology qualitatively delivers all three - plus more - on an unprecedented scale, and provides added value to the core business that is neither land nor labour intensive.