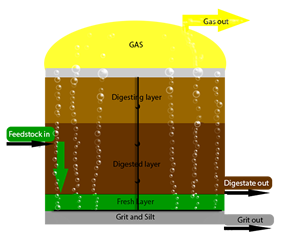

Non Mechanical Gas Agitation

Gas mixing is an extremely efficient low energy mixing system

providing the lowest parasitic load. Combining gas mixing with

de-gritting removes the need for the agitation to keep silt & grit

in suspension.

Gas mixing is an extremely efficient low energy mixing system

providing the lowest parasitic load. Combining gas mixing with

de-gritting removes the need for the agitation to keep silt & grit

in suspension.

This enables the mixing rate to be dictated by the digestion elements; inoculation, temperature stability and the prevention of crusting, enabling not only more control over the process but also further reductions in parasitic load and increased efficiency (gas yield).

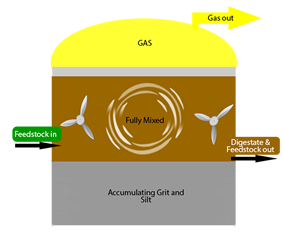

Most conventional digesters are fully mixed systems, which involve continuously agitating the material inside the tank in order to try to keep any grit entering the system in suspension.

In a fully mixed system that is continually loading fresh material and unloading spent material, a percentage of fresh material just loaded will be unloaded straight away.

In a Fre-energy digester, by reducing the agitation, stratification is allowed to occur in the tank. This allows predominantly digested material to be selectively extracted. Reduced mixing does not damage the flora and fauna, but serves to support and encourage bacterial growth. This improved

digestion and resulted in greater throughput and increased gas, hence more profit.

The de-gritting and gas agitation system is designed such that all the serviceable parts are external to the digester. The drive system and bearings are located on the digester roof and can be disassembled without breaking the gas seal.